Testing of the Sceptre: a 155 mm ramjet shell traveling at Mach 3.5, with a range of 150 km, accuracy of less than 5 m, open architecture, and optimized logistics.

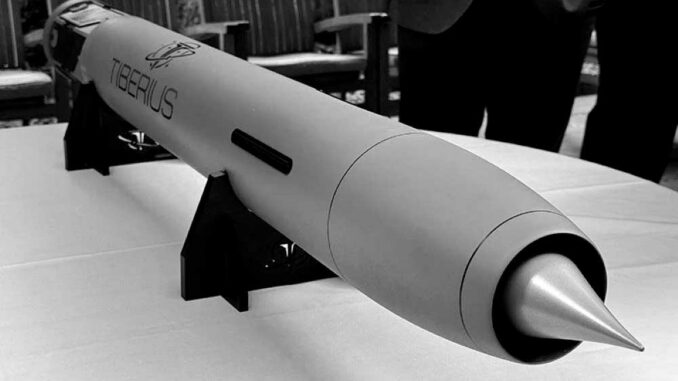

The Sceptre (TRBM 155 HG) developed by Tiberius Aerospace is a 155 mm shell using liquid fuel ramjet propulsion. It redefines the standards of conventional artillery with a range of between 140 and 160 km, a supersonic speed of up to Mach 3.5, and accuracy measured by a CEP of less than 3.5 m, or even 5 m in degraded conditions. Compatible with all NATO 155 mm guns, it features an open architecture and multi-fuel propulsion (diesel, JP-4, JP-8), offering a storage life of more than 20 years and simplified logistics. The United Kingdom is the first launch customer and has signed a rapid trial contract, while the US Defense Innovation Unit is independently validating the results. This project combines high-level technical performance with an agile industrial model inspired by Silicon Valley methods.

The Sceptre concept: a precise technological leap

The Sceptre is a 155 mm shell designed for standard NATO tubes, but equipped with a liquid-fuel ramjet engine. It works by igniting the propulsion system only after leaving the tube, thus avoiding premature wear on the barrel. The shell reaches a supersonic speed of Mach 3.5, equivalent to approximately 4,300 km/h, well above the speeds of conventional shells, which top out at around Mach 2. Its trajectory allows it to reach a maximum altitude of 20,000 m (65,000 ft) before descending on the target, optimizing range and stability. Its announced operational range is between 140 and 160 km, compared to approximately 24 km for a conventional M107 explosive shell, or 100 km for latest-generation guided projectiles such as the American XM1113.

Accuracy is one of the Sceptre’s major strengths. Thanks to a hybrid GPS and inertial navigation system, reinforced by artificial intelligence algorithms, it offers a CEP (circular error probable) of less than 3.5 m, which corresponds to a near-surgical strike. Even in the event of GPS jamming, the error does not exceed 5 m. This degree of accuracy is comparable to that of certain guided missiles, while using existing ground artillery infrastructure. The shell retains a standard weight of 47.5 kg, making it compatible with automated loading systems for 155 mm guns such as the French Caesar, German PzH 2000, and American M109.

Architecture and logistics: simplicity and resilience

The Sceptre stands out for its simplified design. It has only 25 unique mechanical parts, which reduces the risk of failure and facilitates automated manufacturing. The motorization is based on liquid fuel injected at the moment of firing, eliminating the storage risks associated with unstable charges. This approach guarantees a storage life of over 20 years, which is significantly longer than the usual life of conventional propulsion shells.

The choice of available fuels (diesel, JP-4, JP-8) increases flexibility. These fuels are already widely used in land and air forces, eliminating the need for specialized logistics channels. The shell is also designed to work on any 155 mm gun that meets NATO standards, without requiring major modifications to the barrels. In practice, armies equipped with PzH 2000, Krab, Caesar, M109, or K9 Thunder could fire this projectile without complex adaptation. The delayed activation of the motor also eliminates mechanical stress on the barrel, which limits metal fatigue and extends the life of the guns.

Advanced guidance and open architecture

Accuracy is based on a system combining GPS, an inertial unit, and onboard algorithms. The Sceptre is designed to resist jamming and operate in contested environments. It has dynamic trajectory correction capability, thanks to small aerodynamic control surfaces adjusted by artificial intelligence. This correction keeps the projectile on its optimal trajectory, even if the GPS signal is interrupted.

The unique open architecture of the Sceptre allows users to integrate new modules or software without relying solely on Tiberius Aerospace. The hardware and software interfaces are documented to facilitate the addition of additional sensors or specialized payloads. This industrial choice reflects a desire to move away from the closed practices of large defense groups such as Rheinmetall and BAE Systems.

The innovative industrial and economic model

Tiberius Aerospace is inspired by Silicon Valley development methods. The company favors short cycles with iterations every three to four weeks. Prototypes are tested in real or simulated conditions, allowing for rapid corrections. The approach is also based on decentralized production. Tiberius does not handle all manufacturing: the company grants local licenses, allowing armies to set up a national production line in the event of conflict.

The price of the Sceptre starts at around $52,000 (approximately €50,000) per unit, without a specific payload. By way of comparison, the American Excalibur costs more than $380,000 (approximately €366,000). With mass production, the price of the Sceptre could drop to $40,000 (€38,500). The operational impact is clear: to neutralize a fortified target, two Sceptres would suffice, compared to more than 260 conventional M107 shells costing around $3,300 each. The logistical savings are therefore considerable, as is the reduction in collateral damage.

The first customer and independent validation

The United Kingdom is the first customer to have signed a rapid trial contract with Tiberius Aerospace. The exact value has not been disclosed, but the contract covers test firings, performance validations, and a possible pre-production run. The US Defense Innovation Unit (DIU) is conducting an independent validation in parallel to ensure the credibility of the results. The system will be publicly unveiled at the DSEI exhibition in London in September 2025.

This initial adoption is strategic. It positions the United Kingdom as a pioneer in long-range artillery at a time when conventional artillery is undergoing significant wear and tear in modern conflicts. By independently validating performance, the DIU gives the program international legitimacy, particularly in the face of competing projects led by Nammo in Norway with Boeing, and Rheinmetall Denel in South Africa.

Strategic and tactical consequences

The Sceptre is a game changer for modern armies. It offers unmatched firing range for a land-based artillery piece, allowing it to strike safely beyond conventional counter-battery capabilities. With a range of 150 km, a French Caesar battery positioned behind the front lines could reach a major urban or industrial area without entering the danger zone.

Tactically, the Sceptre brings artillery closer to the precision of missiles, while maintaining lower costs. It also opens the way for new uses: targeted saturation of anti-aircraft systems, precision strikes against logistics depots, and long-range support for mechanized units. On the other hand, the open architecture and decentralized production involve risks: data security, supply chain reliability, and quality heterogeneity depending on the licensed sites.

Finally, Tiberius’s approach is not limited to 155 mm. The company is already preparing 120 mm versions, compatible with battle tanks, and is considering adaptations for ground-to-ground missiles. This confirms that the Sceptre is not an isolated prototype, but the first step in a family of precision munitions.

War Wings Daily is an independant magazine.